CNC machining services play a vital role because of the exact manufacturing landscape that we have today, and they provide unmatched accuracy, competence, and versatility. The needs of the industry are high quality, fine tolerances, and quick lead times. CNC machining can be used to fulfil those needs; whether you are brand new to manufacturing or looking for insights on how CNC machining can improve your current production processes, knowledge of this technology is essential.

CNC (Computer Numerical Control) machining replaces hand methods in traditional manufacturing, employing tools that computer models drive to attain consistent and exact outcomes. This process reduces the likelihood of human error and material waste and also ensures that every part produced is made consistently. With applications in aerospace, automotive, medical devices, and consumer electronics, the uses of CNC machining are vast and varied.

What is CNC Machining?

CNC machining (computer numerical control)is a production process where industrial equipment and tools are moved according to pre-programmed computer software. These offer the best in class precision and granular control for machining to convert raw material into final components with maximum possible accuracy every time. Generally, CAD (Computer Aided Design) software generates the instructions (G-codes) that tell the machine tools what to do and where to move in CNC machines.

The Basics of CNC Machining Services

-

Precision and Accuracy

CNC machining is known for its tight tolerances and super-exact specifications. CNC machines help mitigate human error and allow for precision control of tools, thereby ensuring that parts are consistently made with accurate measurements and complex geometries. This precision is essential in fields requiring components to fit precisely (aerospace, automotive, and medical device manufacturing).

-

Versatility in Materials

A great benefit of CNC machining services is that many materials can be machined, including metals (aluminium, stainless steel, titanium), plastics, and wood, which are the most common in prototype/marker lab-scale production. This flexibility enables the decision between mechanical properties, cost-effectiveness, and visual appearance in all fields of material selection mapped into a process.

-

Efficiency and Productivity

CNC machining services offer several benefits regarding efficiency and productivity compared to traditional fabrication methods. After being coded by a CNC mastercam programmer, the machine can execute operations continuously and independently without constant human intervention in the production process, which ensures the availability of machines 24/7 and more work during off-peak hours. This effectiveness is perfect for high volumes and JIT (Just-In-Time) strategies.

-

Complex Geometries and Prototyping

CNC machining excels in producing complex shapes and intricate features that may be challenging or impossible with conventional machining techniques. This capability is essential for prototyping new designs and iterating quickly during product development cycles. By generating prototypes that closely resemble final production parts, CNC machining accelerates time-to-market and enhances design validation.

Key Industry Players

In the CNC machining sector, the providers and manufacturers of essential items and services are numerous. Now we offer you an examination of some key players:

Pintle Hook Supplier

Pintle hooks are a crucial component in towing and hauling as well as a major focus for supply. A good pintless hook supplier ensures pins in this category are of the correct quality, even in rigours situations with machines for CNC machining production. Accurate geometry created by CNC manufacturing services can save lives from being lost by avoiding rolling off cliffs or into traffic in situations with such high requirements and demands. CNC machining services are often used to produce pintle hooks with precise dimensions and high-quality finishes, ensuring safety and performance in demanding conditions.

U Bolts Manufacturer

For the manufacture of u-bolt fasteners, it is not uncommon that companies will utilise precision CNC machines. This technology allows for the creation of enormous U-bolts that can be used in a wide variety of settings. Fasteners more than a metre in length and a thickness that can stand up under loads up to k N/m can be made on these machines, with an output weight limited only by the capacity of the lathe. U-bolts produced using technology such as this are assured to meet specific requirements, ensuring they perform effectively in their intended applications.

Stainless Steel Fittings Manufacturer

Stainless-steel pipes are commonly used in many industrial applications because of their durability and resistance to corrosion. A stainless steel fittings manufacturer will employ CNC machining technology to produce accurate fittings suitable for a lifetime of service with integrated systems, whether in mechanical engineering or beyond.

Advanced Applications of CNC Machining

-

3D Contouring and Surface Finishing

The advantages of CNC are that it may be specifically filed to create intricate shapes and contours that a normal machine could not handle or would be very expensive to implement. The latter is crucial for rapid prototyping of novel designs and quick iteration during the development cycle. By creating prototypes nearly identical to final assembly parts, CNC machining speeds up the time-to-market process and improves design verification.

-

High-Speed Machining (HSM)

Another technique used with CNC technology to improve cutting speed is high-speed machining (HSM). HSM is utilised in industries that value material removal rates as quickly as possible, such as aerospace, defence, and automotive racing.

-

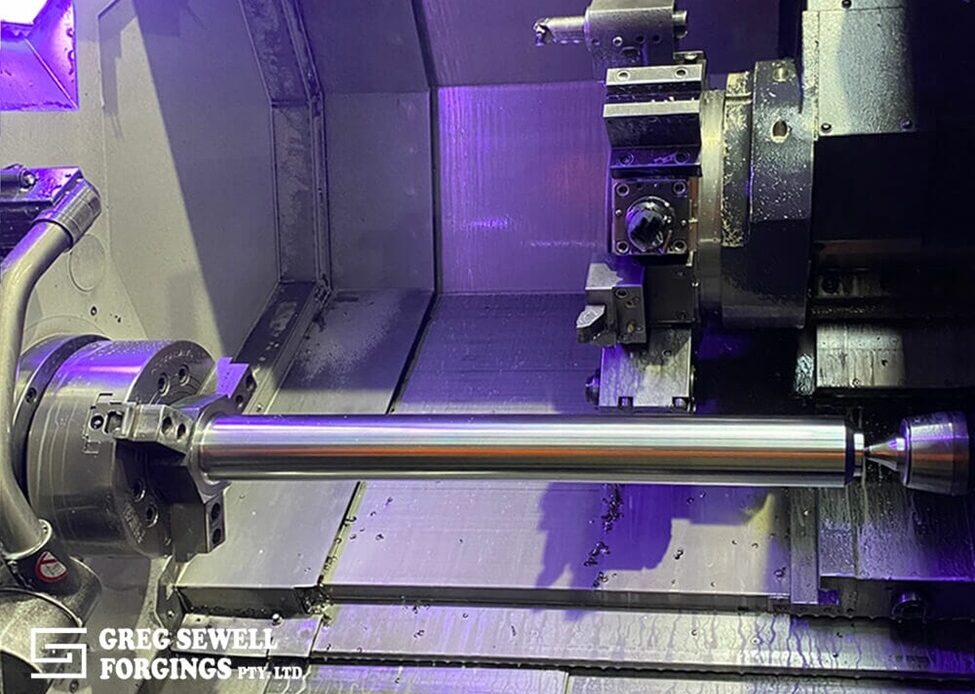

Multi-Tasking and Mill-Turn Machining

Modern CNCs have multi-tasking capabilities, such as one machine performing milling, turning, drilling, and other associated operations in a single setup. It provides a simplified process flow and minimises production setup times, resulting in increased flexibility during manufacturing.

Choosing the Right CNC Machining Services Provider

Choosing the proper CNC machining Melbourne service provider is crucial to obtaining the best results and maximising return on investment. When you look for a provider, these are all the things to take into account:

- Expertise and Experience: Choose someone who knows your industry well and has experience with the workflow that could be tough to handle.

- Technological Capabilities: The provider should use modern CNC equipment and software to supply you with high-quality products very efficiently.

- Quality Assurance: Ensure the provider is certified (ISO, AS9100), strictly adhering to quality standards and precision monitoring.

- Customer Support and Communication: Good communication with an inherent customer support system that keeps clients assembled can persuade potential customers to rely on you whenever they need a project, timeline, or operational hitch.

Conclusion

CNC machining services are the heart of modern manufacturing and provide incomparable precision, efficiency, rigidity and versatility to some industries. CNC technology allows precision manufacturing from complex prototypes to high-volume production runs, supporting innovation and process excellence. Based on the principles and capabilities of CNC machining, businesses needing a way to achieve quality unmatched more effectively to meet their production demands, are complacent when considering service integration into everyday market environments today.